Ehrhardt Automation Systems’ VP Pat Walsh Discusses Automation, Growth, and New Workers.

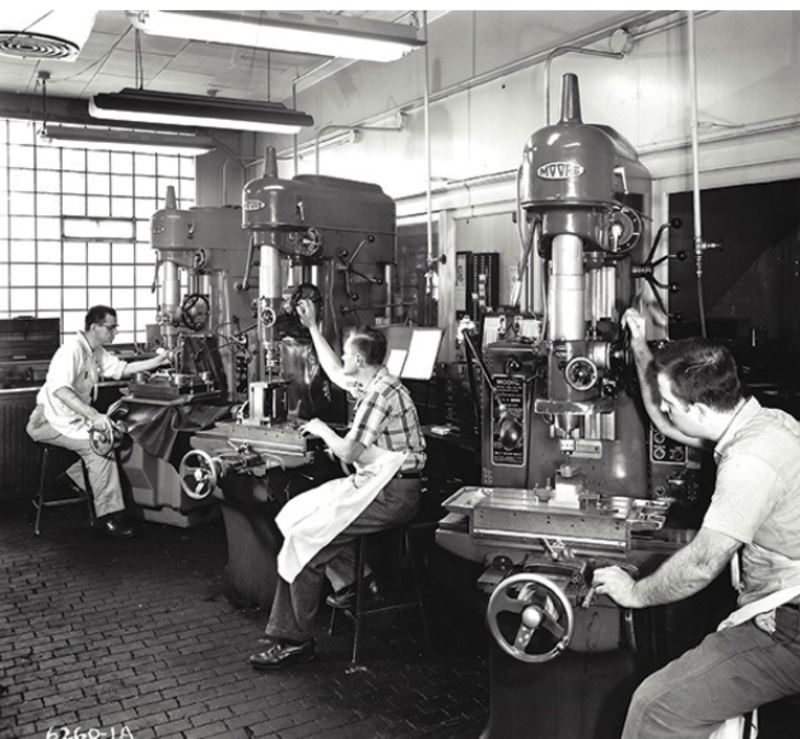

Willis Ehrhardt founded Ehrhardt Tool & Die in a horse stable in St. Louis in 1937, and for the next several decades, built a reputation as a premium tool and die house.

In 1970, Ehrhardt sold the business to Alco Industries, and in 2014, it was acquired by Dunes Point Capital (DPC). Over the years, and through several name changes, Ehrhardt slowly expanded from tools and dies and slowly incorporated more automation into its processes and products, largely specializing in the HVAC and appliance markets.

Vice President Pat Walsh has been with the company for nearly 40 years and has witnessed its growth and evolution over the years firsthand. We spoke with him about Ehrhardt’s biggest and boldest pivot to date. After acquiring the company, DPC realized that they would not be able to achieve their growth and expansion goals without bringing fully automated solutions to their customers.

“A number of interrelated factors led to this strategic decision,” said Walsh. “The capital equipment necessary to maintain a tool and die shop is expensive. If your goal is to double production, you need to make significant new investments in capital equipment and must budget for the cost of perishable tooling as well. Additionally, finding qualified employees is an increasingly difficult challenge. Larger companies offer significantly higher starting salaries, and SMBs can no longer count on hiring the cream of the crop from technical colleges. There are far fewer toolmakers out there; younger people are not moving into this area, and pretty extensive training is necessary.”

By changing its business focus to automation integration and designing and building automated assembly equipment and fully integrated solutions, Ehrhardt can provide more value to its customers while lowering capital equipment requirements, variable labors costs, and overall risk. Ehrhardt kept its core but added automation around it. Automation was simply the most efficient way to increase business.

Fewer of Ehrhardt’s customers have tooling experts in their plants every year, and they are looking for automated solutions for this reason. In the past, many plants would have done the equipment integration themselves. Now they want the integration done for them – a turnkey solution so they wouldn’t need to set up production lines, troubleshoot problems, or train employees. Ehrhardt can do all of this.

The company, which currently has about 100 employees, also rebranded and changed its name from Ehrhardt Engineered Solutions to Ehrhardt Automation Systems this year. It is also expanding into the automotive and medical device sectors.

“At Ehrhardt, we see the benefits of automation extending well beyond basic cost justification. When factories cannot fill open labor positions, they can’t meet production requirements, much less grow. Automation also helps companies attract workers because the younger generation interested in working in manufacturing is more likely to choose a company that is actively investing in automation solutions and robotics and is poised to be competitive in the future.”

The cost equation for investing in automation was initially most favorable for sectors like automotive manufacturing with low-mix, high-volume production needs. But as the cost of automation comes down, it makes financial sense for factories that have a wide range of higher-mix, lower-volume production runs.

“We don’t see our customers replacing workers with robots; they are adding automation and retraining their valuable employees for positions that include working with robots and using automation solutions.”