The concept of Silicon Valley as an epicenter of innovation is entrenched in the American consciousness. Thinking so is natural, as the Valley plays home to research and academic institutions (Stanford, Caltech, UC Berkeley) long known for producing innovative people, the internet, and integrated circuits. As something of a contradiction, the stories of computer companies founded in a garage (Hewlett-Packard, Apple) border on legendary and provide a distinctly American edge to our image of tech entrepreneurialism. Add in venture capitalists who support commercial growth (Intel, Oracle, Cisco, eBay, Netflix) and who are as likely to meet new people at a collaborative workspace as they are cruising the halls of academia, and the result is a region of dynamic forces pushing today’s tech boundaries.

While the ingredients to our innovative secret sauce seem ordinary to Americans, they remain somewhat enigmatic to others. So that AMT’s European counterparts could gain a deeper understanding of the unique culture of Silicon Valley, AMT coordinated a three-day trade mission for a delegation from CECIMO, an umbrella organization serving the common interests and values of the European machine tool and related manufacturing technology industries.

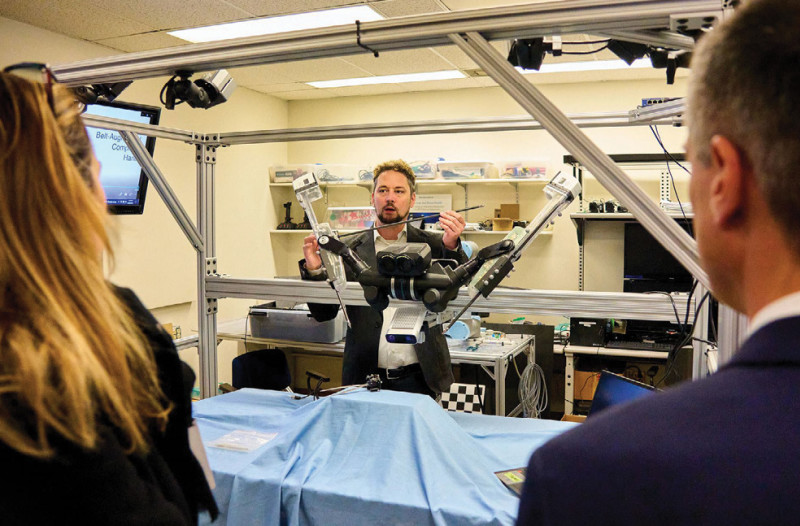

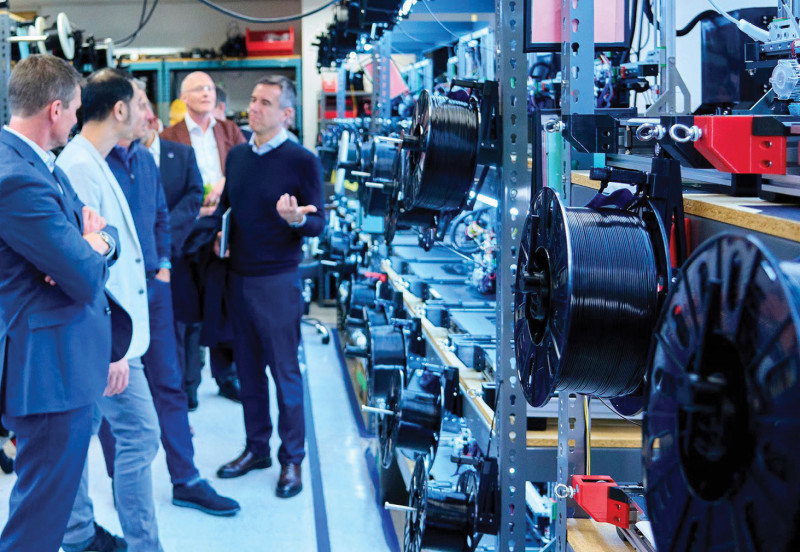

Ryan Kelly, the general manager of AMT’s San Francisco Tech Lab, arranged for the delegation to visit 11 innovators in late March. The companies visited ranged from the world-renowned to startups: NVIDIA, Meta, Velo3D, Rapid Robotics, Autodesk, Arris, SRI, HEIDENHAIN, OhmniLabs, Urban Machine, and Lumafield.

“The Silicon Valley culture, approach to innovation, and ability to build and scale companies deeply impressed them,” says Douglas K. Woods, AMT president. “They realized that they could be more connected to the business models and disruptive technologies that create transformative companies.”

As an example, Kelly says, “A typical entrepreneur with an automation background would think, ‘I’m going to create a robotics company.’ In Silicon Valley, that entrepreneur thinks, ‘How can I provide the absolute best possible user experience to my customers through a robotics-as-a-service business model, borrowing from lessons learned from the software-as-a-service business model that dominates software today?’”

“The trip was truly enriching, eye-opening, and inspirational,” says Filip Geerts of Belgium and the director general of CECIMO. “I witnessed numerous technological advancements that were nothing short of a glimpse into the future.

“Common themes that stood out across the visits included graphics, augmented and virtual reality, digital twins, software, sustainability, and use of AI but also time-to-market services rather than products.

“It also permitted me to see firsthand why the region is so conducive to technological innovation: entrepreneurialism, financial access, presence of top universities, and also a hip community with a lot of sunshine. I had the opportunity to engage with a diverse range of companies and startups. All in all, I had a wonderful time with our colleagues of CECIMO and friends of AMT. It was, for me, a remarkable experience that left me feeling inspired.”

“This mission helped CECIMO leaders enrich their knowledge about how to leverage tech innovations to develop new manufacturing services and products,” adds Tim Shinbara, AMT chief technology officer. “Automation, digital manufacturing, augmented reality, additive manufacturing, or a combination were being leveraged at the companies we visited.”

For their part, the U.S. participants in the trade mission made high-level connections with some of Europe’s leading manufacturers and manufacturing organizations. CECIMO delegates included:

Director general of CECIMO (Belgium)

President of AFM Cluster and CEO of Fagor Automation (Spain)

Director general of AFM (Spain)

Secretary general of Swissmem (Switzerland)

President of UCIMU-Sistemi per Produrre and CEO of FICEP spa (Italy)

CEO of EMCO GmbH (Germany)

Head of business development at EMEA at RENISHAW and chairman of CECIMO’s Additive Manufacturing Committee (United Kingdom)

President of CECIMO and CEO of EMAG (Germany)

CEO of Hembrug BV (Netherlands)

The U.S. companies also saw huge possibilities in the greatly untapped potential for their technologies if they adjusted their view of its use.

For example, the technology behind Omniverse (Nvidia) or the Metaverse (Meta) aims to provide a virtual world where different tools, software, and hardware can collaborate seamlessly.

“The technology was catalyzed by gaming,” notes Kelly. “That’s interesting and entertaining on a consumer level, but it could be transformative if applied to manufacturing.”

Sarah Birdsell, technology lead, Reality Labs executive engagement team at Meta, says: “Meta is establishing itself as a key partner in building the Metaverse – a new immersive computing platform that is designed for a sense of presence and is anchored on principals of interoperability and continuity.

“Meta was honored to recently host the CECIMO leadership and visiting manufacturing leaders on its recent inspiration tour to the Bay Area; for some it was the first time doing work in virtual reality, and the excitement was palpable as they went through the Meta data center training experience.

“At Meta we build technology to connect people through community-first experiences – learning from this contingent on their top-of-mind priorities helps us to establish how we best show up in the market and how we can support the manufacturing sector as it works through modernization programs.”

“The Silicon Valley and manufacturing technology communities evolved separately,” says Woods. “Until recently, they did not interact routinely. At AMT, our goal with events such as the CECIMO trade mission is to deepen understanding and uncover synergies so they can leverage each other’s strengths and market potential.”

If you have any questions about this information, please contact Travis at tegan@AMTonline.org.