Today, we dive into machining centers. Now, you may be thinking, “You don’t know what a machining center is?” But I do – or at least I do now since joining AMT – The Association For Manufacturing Technology in June of 2021. Simply, it’s a computer-controlled machine that features a platform to clamp a workpiece in place and a cutting tool with an automatic tool changer. The tool moves around the piece, cutting, drilling, boring, or milling as the operator requires.

Like most genius inventions, the machining center was designed to make people’s jobs easier (looking at you, spell check). Think of it like a smartphone. While we used to use phones simply for calls, we now have calculators at our fingertips (even though our math teachers said we wouldn’t) as well as the internet, a camera, and social media – all of which make our lives easier and smoother.

Machining centers have a similar function: In addition to making a job easier, they are more cost-effective for production, more accurate, and, of course, faster. This is because rather than having to take a machined piece from tool to tool to make a part, everything can be done at one station – a one-stop shop. It helps streamline the process and creates uniformity in all the parts that the machine creates. Modern machine centers are also highly automated, which helps augment the productivity of a company’s workforce in a positive direction and, by extension, helps the companies save money. Now, that being said, the machines themselves require a higher level of technical expertise for operators and machine maintenance personnel. They can also be less intuitive than ordinary machine tools.

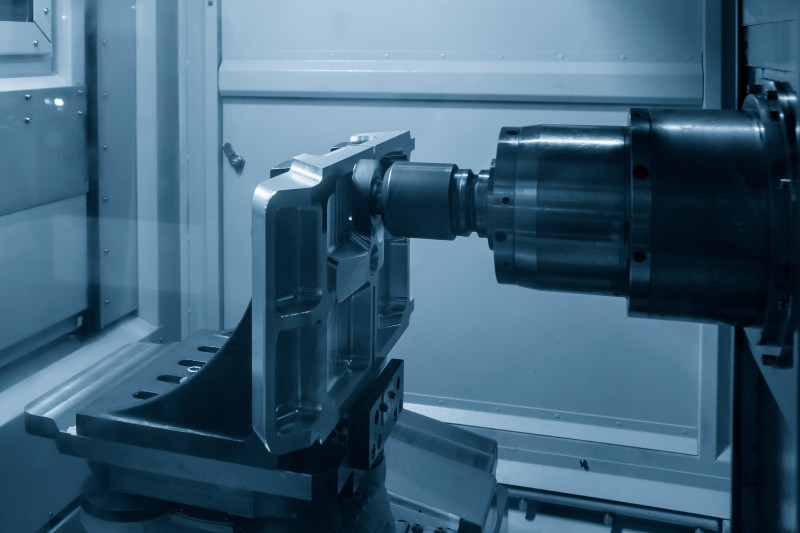

Machining centers can come in many shapes and sizes but are primarily horizontal or vertical. According to Mastercam, “A horizontal milling machine, also known as a horizontal machining center or HMC, features a cutting tool that is oriented horizontally. Their horizontal design allows chips to fall away naturally and safely.”

Horizontal Milling Machine

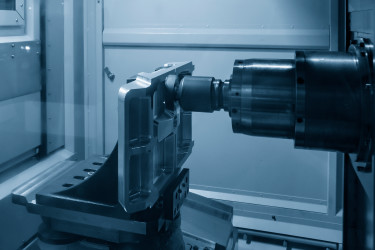

In contrast, a vertical milling machine is “the most commonly used milling machine, but there are two main styles: turret mills and bed mills. In both vertical milling machines, the cutting tool is mounted vertically.”

Vertical Milling Machine

So, how are machining centers affecting the industry today? And why should you use them? Well, if you have visited a trade show recently (like IMTS), you would have seen machining centers all over the show floor. At each IMTS, there are at least 150 exhibitors who either bring their machining centers, use them in their business, or create parts for them. If you want to see the absolute latest in machining centers, you can visit IMTS.com and search “machining centers." Right now, nearly 200 companies come up featuring machining centers. See the list here. This alone tells us what companies are buying, and besides the above reasons that they have for using them (like increased efficiency and helping them save major dollars), they also increase accuracy. And who doesn’t love something that is both efficient and accurate?

So, there you have it. Machining centers: the one-stop shop of manufacturing technology. To summarize: They make people’s lives easier, improve accuracy, and while it may sound like a Best Buy or an electronics store, it decidedly is not, contrary to what I thought when I first heard the phrase.

Look, when you are surrounded by the smartest people in the room, remembering what your elementary school teachers told you can be hard: “There is no such thing as a stupid question.” As an adult, it is easy to forget that. So, that is what this series is for: the non-tech people working in manufacturing who are afraid to ask those questions. We want to teach important basics about manufacturing, such as how they have changed and still influence the industry today. While I am still new to the manufacturing world, I can safely tell you that I love it. I’ve collected tons of questions I’ve wanted to ask since my first day here, and I can’t wait to answer them for you.

Make sure to register for IMTS 2024 and see machining centers in action yourself!